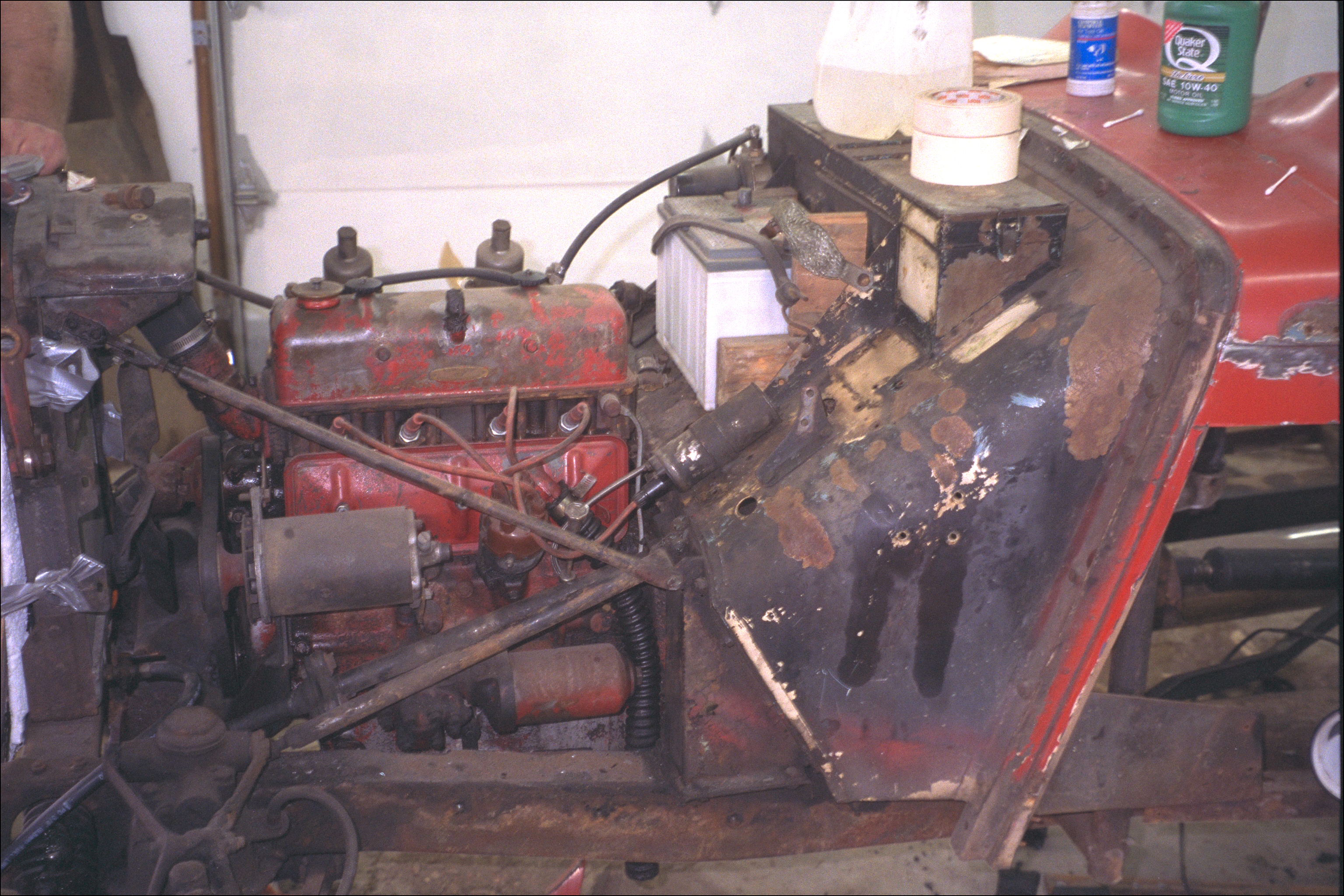

LC0aO2g5: Tear Down & Engine/Drive Train ^

Disconnecting the engine from electricals,and fuel lines, then drive shaft and transmission.

With the radiator removed, we pulled the engine. Bottom up on the work bench, we took off the

oil pan and took out the crank shaft and pistons. A discovery: the cylinders had already been

over-bored. This implied I could not renew the engine without buying a replacement block or

inserting “sleeves” in the cylinders and then machining them to the diameters required. Tom

did not have the equipment to do that and recommended I take the engine to a performance motor

shop nearby. He negotiated a deal as a professional mechanic; they agreed that he could provide

the parts, which I paid for, to avoid any parts-markup by the engine machine shop.

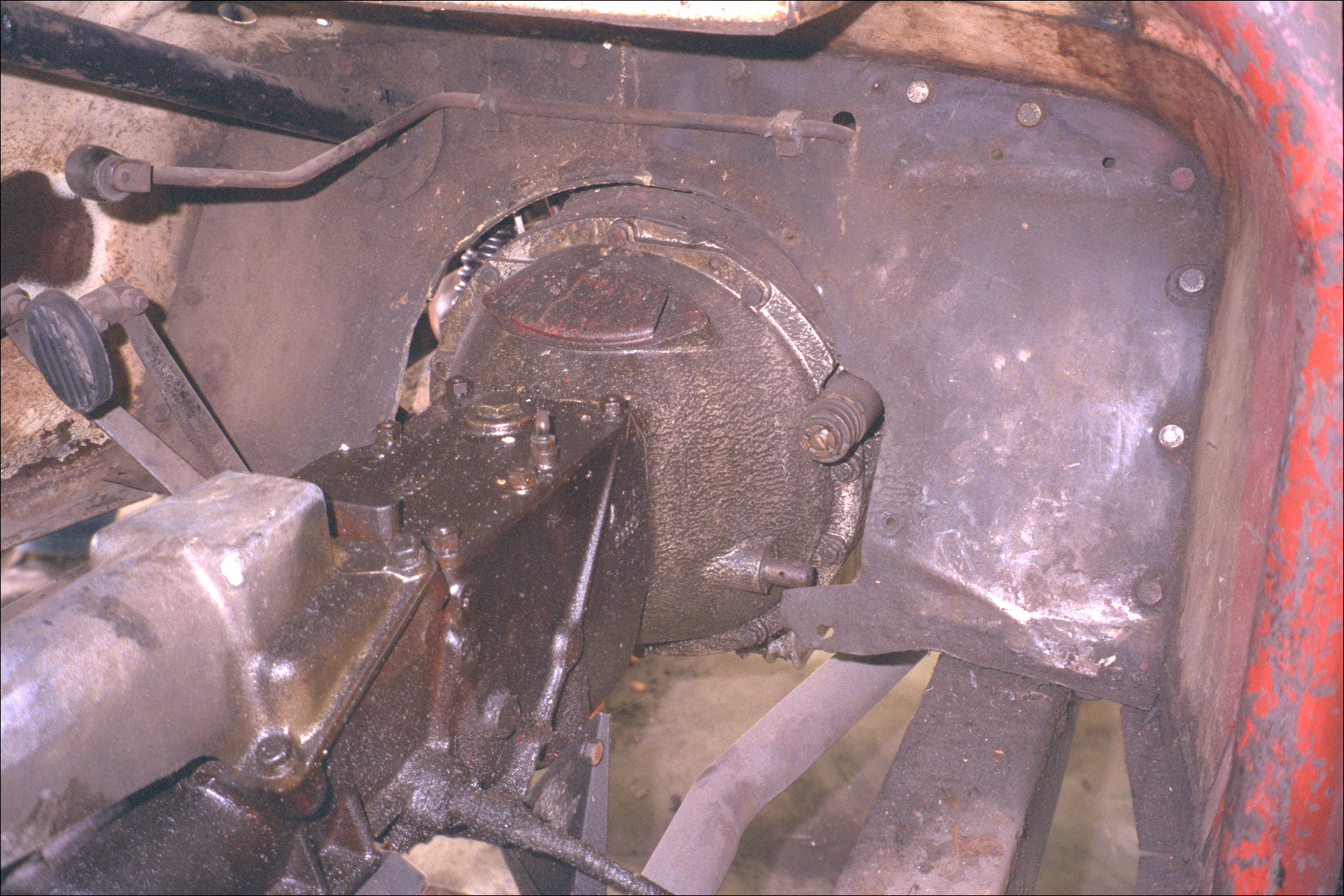

Inspection of the gear train showed one gear had a small portion of one tooth broken off.

There was no need to disassemble and rebuild it.